Service

Moisture-Proof Methods of LED Displays

For LED displays, moisture will cause problems such as string lights, dead lights, short circuits, and damage to the lamp body, resulting in performance failures! The pervasive water vapor has become the number one enemy of the LED displays! Therefore, in order to ensure that the LED display can work well in wet weather, we must do a good job of preventing moisture. The details as follows:

Indoor Fixed LED Displays

Under the ambient humidity of 10% to 65% RH, the LED display is turned on at least once a day, and it is guaranteed to work generally for more than 4 hours each time.

If the ambient humidity is higher than 65%RH , the environment of the screen should be dehumidified, and the display screen should normally work for more than 8 hours a day; the relevant doors and windows should be closed at night to prevent the screen from being damaged by the return of moisture.

Indoor Rental LED Displays

- Put it immediately into the flight case for airtight storage after use.

- In every flight case, there must be no less than 50g of desiccant or hygroscopic bag; And regularly check the desiccant or hygroscopic bag for failure, and replace it every 2 months.

- Under the ambient humidity of 10% ~ 65%RH, the display should be taken out oflighting work (video) for more than 2 hours every half month.

- When the ambient temperature exceeds 65%RH, the display should be taken out and lighted up (video ) for more than 2 hours every week.

- The screen should not be exposed to rain or water when working. If it is accidentally wet, it should be wiped dry in time and dried with a hair dryer. At the same time, after the screen is placed for 2 hours, it should be litfor 2 hours.

- It is strictly forbidden to use the indoor rental screen as an outdoor rental screen, especially in an open-airenvironment.

Outdoor Fixed LED Displays

- Configure a temperature and humidity monitor at the installation site of the outdoor LED display to monitor the humidity around the screen in time;

- After the first rainy day or heavy rain after the screen is installed, check whether there is moisture, water droplets, water vapor, etc. inside in time;

- Under the ambient humidity of 10% – 85%RH, open the screen at least once a day, and each time the display works normally for more than 2 hours:

- If the ambient humidity is higher than 90% RH, the use environment of the screen should be dehumidified, and the display shouldnormally work for more than 4 hours a day.

Outdoor Rental LED Displays

The outdoor rental LED display must be powered off immediately when it encounters rain during use. If it is too late to dismantle the screen, cover it with a rainproof cloth prepared in advance. When it is sunny, take the cabinet out to dry. Open the back cover of the cabinet and blow it dry with a fan. Then hang in a ventilated and dry room for more than 8 hours. Lighting under low brightness for more than 4 hours to ensure fully dissipating of the moisture in the electronic components.

LED Modules

- Raise the ground

When storing, use pallets or other objects to elevate them, and do not directly touch the ground.

- Control humidity

Install a temperature and humidity monitor in the storage environment, and control the ambient humidity below 60% RH.

- Dry storage

When the unsealed LED module (unit board) is stored, it needs to be repackaged and put in a suitable desiccant.

If the LED Display is wet, what should be done to remedy it?

- Quickly dehumidify

Use a fan (cold air) or other dehumidifying tools at the fastest speed to dehumidify the damp Led screen.

- Power-on aging

The completely dried screen body is energized and aged, and the brightness (all white) is adjusted to 30%, 60%, and 100%, respectively, for 12 hours of aging.

In a word, whether it is indoor or outdoor, the most effective way to avoid moisture damage to the function of the LED display is to use it frequently. The display in the working state will generate some heat, which can evaporate some water vapor, which greatly reduces the possibility of a short circuit caused by humidity. Therefore, the LED display that is used frequently has much less impact on humidity than the display that is not commonly used.

Step-by-step Purchasing process of LED Display (For new importer)

As it might be the first time for some customers to import LED display from China, hope this article is helpful for you to avoid any “Surprise”. For some experienced purchasers, just skip this article or welcome your valuable advice & supplement.

Step 1: Check summary cost & possibility

* LED Screen hardware & software

Two points to be mentioned for customers to do inquiry with LED display suppliers:

- Better to send a picture or a design draft of the installation position, to show how it is to be controlled & installed. So that the supplier can offer a matched solution of control system (Syn. & Asyn. 这里可以设置点击跳转到同异步区别的那篇文章), and matched models to fit front/back installation & front/back maintenance.

- When comparing quotations from different suppliers,make sure we’re comparing apples to apples. Check if the LED, power supply, driving IC, aviation plug, etc are the same.

*Structure to install the screen

- Get the CAD drawing of the cabinet from the supplier

- Show the drawing to the local structure supplier to check frame part cost

- Check with the installer for installation cost

* Certificate required

- Get the certificate requested for Customs from suppliers: such as CE for EU countries, and Saber certificate for Saudi Arabia.

- Local certificate: Some projects, especially wall-mounted LED screen requires building certificate, which would cost time & money.

* Electricity needed

Check power consumption for the full screen & if can fit. There’s some customer feedback as it’s an old building & impossible with high power consumption, finally he make it with an energy-saving model (这里可以设置点击跳转到EV960或者是节能屏页面) & size adjusted to smaller one.

* Shipping cost

- Get the pickup address, estimated shipping data & better dimensions of the package to check the shipping cost.

- If by sea, destination cost is better to be mentioned, as it’s to be paid when goods arrive at the destination port, and some customers won’t notice this part. Such as unloading, THC, PSC, Handling fee, port congestion surcharge, etc, get the charge standard from the forwarder together with the shipping rate.

⭐Pay attention to the trend of rate to go up or down, and leave some space when quoting to the end user.

* Tax & Duty

Check with the local broker for the tax & duty to be paid for the LED display. For example, there’s zero tax with 15% VAT (Which can be refunded) in some countries such as EU, while there’s ≥20% duty for other countries such as Jordan, Brazil, USA, etc.

* Timeline

Maybe you have signed a contract with your customer (The end user), and the screen is needed to be installed at a certain time, the timeline has to be taken into consideration in advance.

For example: For LED module & accessories order, production time would be around 7 working days; For LED screen order, we can rush it within 30 working days. Plus shipping, operation of Customs clearance & domestic transportation, if time is too urgent, it’s better to purchase stock locally.

Step 2: Pay the deposit & place order

After the previous investment, and compare cost & budget, and negotiating with some suppliers, you’d select a trusted manufacturer to place the order.

- Payment terms

For most factories, 30% deposit before production, 70% balance before delivery is accepted. Though there are some of our customers who pay 100% payment before production for trust, the advantage is to save bank cost & no need to wait for the balance after goods ready.

While for the first time cooperation it’s suggested to leave some balance to be paid when you see the screen all tested well.

- Arrange production

After the deposit is well received & all details are confirmed, the manufacturer will arrange production, usually, it takes 7-30 working days for production, so the stock would be quicker.

Step 3: Production monitor

- Some customers would pay a visit to the factory, while during COVID-19, you may have a third party in China do an inspection during production or just after the goods are ready.

- Mostly it’s in the supplier’s own inspection system, and they will offer an aging test (Usually 72 hours before shipping) video.

Step 4: Pay the balance & arrange shipment

- After all is tested well, get the balance paid.

- Book space near goods ready date, usually factory can assist with the shipment arrangement.

- If by express: Connect express agent with supplier for pickup, or just offer collect account to the supplier.

- If by air: As air cost usually update once or twice per week, if space is NOT tight, just book space on Monday of the week that screen ready. Book 1 week or longer in advance if space is overbooked.

- If by sea: Sea rate is usually valid for half month or 1 month.

Step 5: Build structure

This part can be done just after the order is placed if the project is urgent so that you can install the screen once get it without waiting for the structure to be built.

Step 6: Customs clearance & delivery from port to warehouse

- If by express, it’s DDP (door-to-door service), you only need to wait for your screens at your warehouse.

- If by air, it’s delivered to the airport, and you need to contact local broker for Customs clearance & pickup from the airport.

- If by sea, it’s delivered to the seaport, the destination forwarder will contact you to pay the destination cost, and you will need to contact local broker for Customs clearance & delivery from destination port to your warehouse.

Step 7: Test & installation

- Check if the cargo is in good condition once received. If anything damaged, pls contact the supplier at once.

- Test it in your workshop if time allowed.

- Aging test starts with low brightness to avoid burnout, especially for long-term transportation such as by sea. Sometimes it would cost 2 months or longer, and there might be moisture problems during transportation.

- Make a connection file according to the diagram, for example, we usually have the full-screen order configured before shipping, and save the RCG file.

- Install the LED display on site.

There’s always something unexpected happening, and nobody hopes so. That’s why it’s better to plan ahead. Meanwhile, it’s very important to get a reliable on-call supplier other than a supplier with an attractive price.

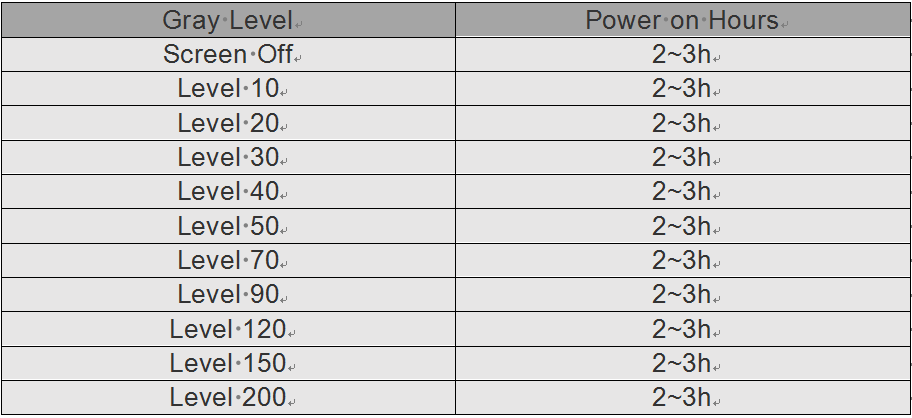

Power-On Hours for Different Gray Levels

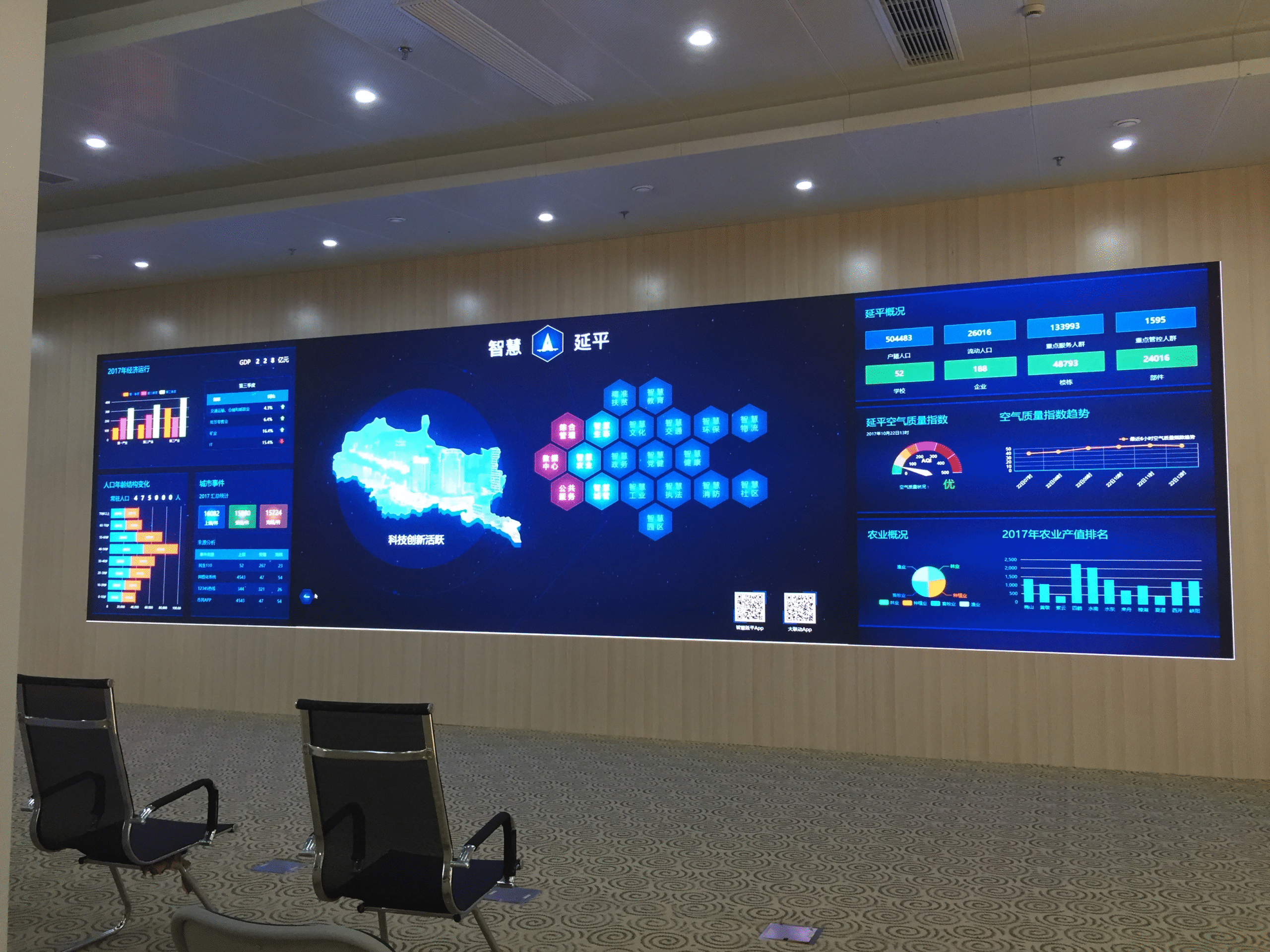

Fine-Pitch LED Display in Security Market

In 2023, the birth of ChatGPT caused a storm in the field of artificial intelligence, and the security industry deeply integrated with artificial intelligence was also brought to the forefront. with artificial intelligence recreated the high ground and the Internet of Things technology continued to climb, the security market is also facing new challenges. After years of development, the security market has grown into a trillion-dollar market, and intelligent security has become the main theme. Its application scenarios involve public security, parks, buildings, finance, transportation, culture and education, health and other scenarios. The diversification of terminal display scenarios makes LED display widely used in its field. In the process of its popularization, various display technologies “compete for each other” in the field of security, but in the end only the fine-pitch display won the “favor”. Why is it? This has to start from the display demand of the security market.

What kind of display screen does the security market need?

The most common LED display in the security market are used in the fields of security monitoring and command and dispatch. The application of security monitoring in all walks of life has become more and more frequent and indispensable, and the video monitoring system is an important part of the security system of. As a terminal for video information output, video monitoring terminal displaying equipment completely display all the monitored pictures clearly on the screen, and can also switch between large and small pictures flexibly, conveying accurate, real, intuitive, effective and rich content. As an important part of the security chain, the terminal display has a long-standing requirement for clarity.

The modern command and dispatch center is the hub of centralized data. The screen of the command center is considered to be the top application of the industry pyramid. The ability to display details on the screen directly affects the success or failure of the work of the command and dispatch center.

From this point of view, the security market’s demand for terminal display equipment focuses on high-definition.

From the past history, the display terminal of the security industry has experienced the CRT era, and then to the visual impact brought by LCD to the industry, and then to the emergence of DLP and LED splicing technology, the market is constantly accepting new technologies and constantly eliminate outdated product. Until 2016, terminal display devices in the security market ushered in an iterative turning point. Before 2016, the LCD splicing wall almost monopolized the public security market, but in 2016, the price of fine-pitch LED screen products continued to decline, and some products have entered a level comparable to 3.5mm LCD in the price range, and the display effect is basically the same, which meets the demand of the security market; Compared with other displays, the fine-pitch LED splicing screen has a series of advantages such as high-definition, high brightness, high color saturation, low power consumption, and long service life, which makes it quickly favored in security monitoring.

On the other hand, the demand for large-screen security displays is also changing. With the development of intelligent technology and the increase of intelligent applications, the value of the security system is changing from a simple “viewing screen” to an “information center”. This change has increased the gold content of large-screen security screens, and also enabled some customers to bear the “higher” construction costs of large-screen security screens. The latter is not good news for LCD splicing, which has long relied on price advantages to win.

In the whole, with the acceleration of the national informatization process, the large-scale construction of infrastructure, and the government’s high attention to the field of security monitoring, as a terminal display device for security monitoring, fine-pitch LED splicing screens have also gained unprecedented development opportunities. And with the decline of prices and the advancement of technology, fine-pitch display screens gradually occupy the large-screen security market, while LCD displays with slightly inferior display performance in the same price range gradually fade out of the security market.

Security visualization, application requirements promote display technology upgrades

The scale of the security display application market continues to expand. According to the research data of Luotu Technology, the scale of display equipment in China’s overall security market in 2021 will be 21.4 billion yuan, a year-on-year increase of 31%. Among them, monitoring and visualization large-screen equipment (LCD splicing screen, fine-pitch LED screen) has the largest market size, accounting for 49%. It can be seen that the terminal display demand in the security market has been growing at a high level, which has also injected impetus into the display technology upgrade of LED displays. Fine-pitch display screens are favored by security terminal displays, and their growing demand has also accelerated the upgrading of LED display technology. Ultra-high-definition technologies such as 4K/8K and COB encapsulation are also gradually being applied to LED display products.

Achieve ultra-high-definition picture quality 4K/8K

Under the background of ultra-high-definition display era, security terminal display is the starting point of ultra-high-definition video technology. With the acceleration of smart city management and the development of the ultra-high-definition era, the security market has higher requirements for high-definition displays in monitoring, command and dispatch. For ultra-high-definition fine-pitch LED displays, the smaller the dot pitch, the easier it is to meet the display requirements of 4K and 8K full high-definition resolution for display terminals in the market. Enjoy more comfort. As a result, Mini/Micro LED technology has also entered the security display.

analyzing from the performance of various screen companies at the 2021 Security Expo, LED displays have achieved ultra-high-definition image quality technology, and the application of Mini/Micro LEDs has become more than capable. Many companies combine Mini/Micro LED technology layout display products to provide visual smart security solutions, further improve the overall display effect and operability of the security command center, and create smart security, smart City, improve the level of urban management services, and realize scientific, refined and intelligent urban management.

The addition of 3D and 8K visual effects allows LED fine-pitch screens to realize “detail recognition”, which improves the “transmission and display” performance requirements of the security display system, and is conducive to the high-quality development of security display.

From the initial “technical melee” to today’s “fine-pitch home”, the security display market has also experienced many collisions and exploration stages between technology and the market. With the entry of Mini/Micro LED technology, LED displays can also be combined with face recognition technology, video processing technology, sound source positioning, VR, AR and other new technologies to help intelligent and high-definition security display.

COB LED Display VS SMD LED Display

After experiencing a trough in 2022, global LED display market demand is steadily recovering in 2023. SMD packaging technology is still the mainstream, but as the market demand for small spacing continues to rise, the market share of COB packaging technology is also rising steadily. COB is becoming the mainstream technology in the industry that major manufacturers are competing to develop. So what are the main differences between COB and SMD?

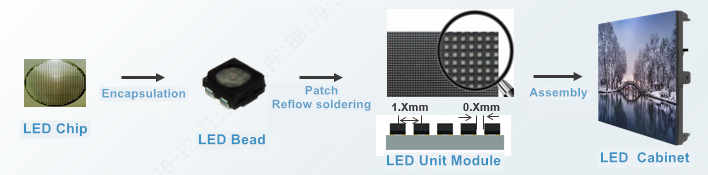

Let us first understand the production process of both:

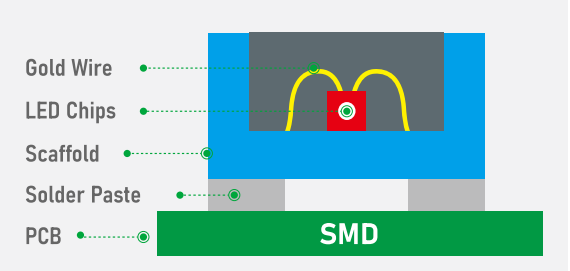

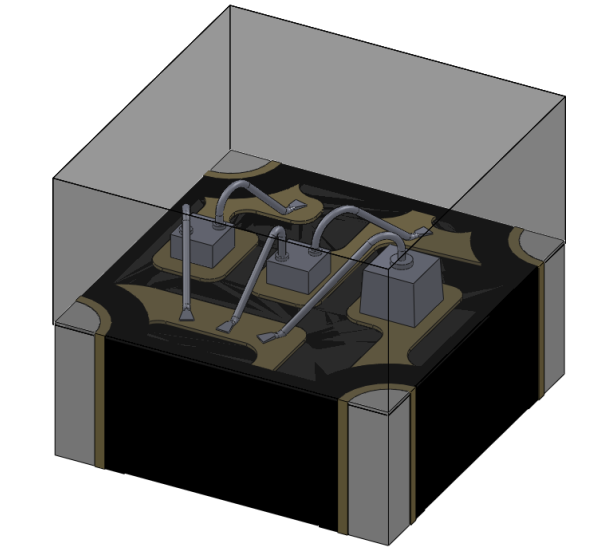

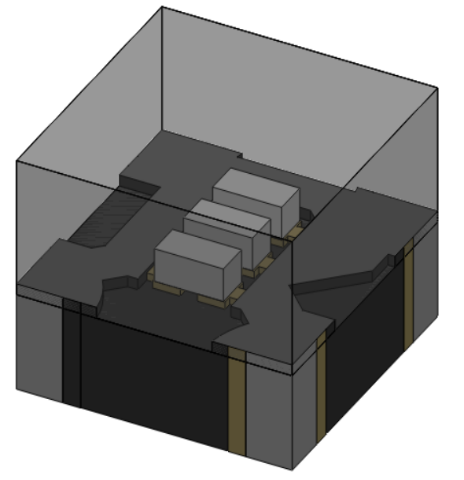

The SMD technology route is to package the light-emitting chips into lamp beads, weld the lamp beads to the PCB board to form a unit module, and finally splice them into a whole LED screen.

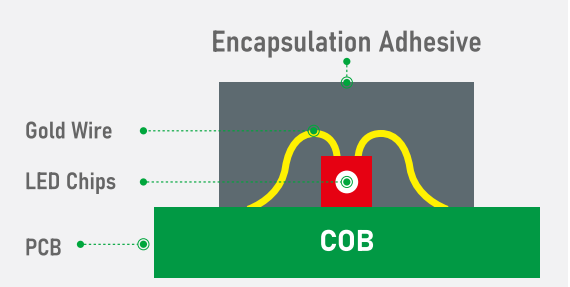

The COB technology route is to directly weld the light-emitting chip to the PCB board, then cover it as a whole to form a unit module, and finally splice it into a whole LED screen.

Main differences between COB and SMD

1. Stability

The SMD method uses a lamp bead bracket and epoxy resin. Due to the different expansion coefficients, it is easy to cause the bracket and the epoxy resin package to fall off during the reflow soldering process, causing gaps to appear. In the later use, the dead light phenomenon will gradually occur, resulting in a higher defective rate. However, SMD is easy to repair on-site and is conducive to later maintenance.

The COB integrated package does not require reflow soldering to attach the lamp, which avoids the problem of gaps between the lamp bead holder and the epoxy resin caused by high-temperature welding in the welding machine. The product is less prone to dead lights after leaving the factory. The surface is encapsulated with a lens to effectively protect the light-emitting diode chip and enhance its protection capability. However, due to the overall coating, it cannot be repaired on-site and needs to be returned to the factory for repair using professional equipment, which is more inconvenient.

2. Heat dissipation

SMD products mainly dissipate heat through colloids and four pads. The heat dissipation area is small and the heat will be concentrated on the chip. Over time, it will cause serious light attenuation and even dead light, which will reduce the service life and quality of the display.

COB-integrated packaging products encapsulate the chip on the PCB board and dissipate heat directly through the entire PCB board area. The heat is more easily dissipated, thereby extending the life of the display.

3. Performance

The lamp pin pads of the SMD product display are exposed, and short circuits between the lamp pin pads are prone to occur when exposed to water or moisture; the mask used is uneven and difficult to clean when it is stained with dust; the metal bracket used is easily oxidized; the exposed lamp pin pads are easily affected by static electricity, causing the lamp to die. There are deficiencies in waterproof, moisture-proof, dust-proof, anti-static, and anti-oxidation properties.

COB integrated packaging display adopts panel packaging technology, without the problem of exposed lamp pins, and has functions such as moisture-proof, dust-proof, and anti-static.

4. Viewing angle

The SMD display screen has a reduced viewing angle due to reasons such as the high packaging of the lamp cup, accuracy errors during the patching process, and uneven surface placement, the viewing angle is about 140°.

The COB small-pitch display integrated package does not require mask protection, and the left and right viewing angles are increased to 170°.

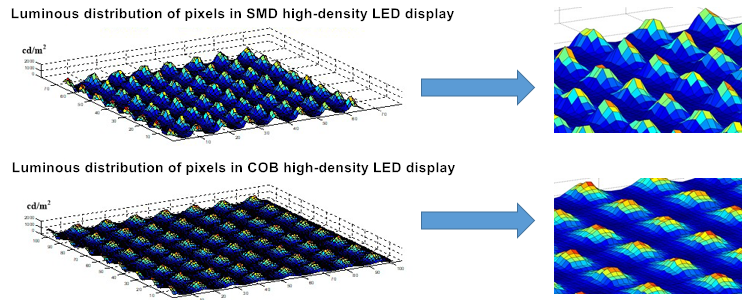

5. Image

SMD screen lamp beads emit light as a single unit, presenting a point light source effect. COB screens are covered with a film on top of the light-emitting chip, and the light source becomes a surface light source after being scattered and refracted by the film. Compared with point light sources, surface light sources have a better overall visual perception, no graininess when viewed, and can reduce the stimulation of the light source to the human eyes, making them more suitable for long-term close viewing.

After the COB screen is integrally packaged using a new process, the contrast ratio can be higher, reaching more than 20,000:1, while the contrast ratio of the SMD screen will not exceed 10,000:1. In comparison, the viewing effect of a COB screen when viewed from the front is closer to that of an LCD screen, with brighter colors and better details.

However, because COB screens cannot sort individual lamp beads with similar optical properties like SMD screens, the entire screen needs to be corrected before shipment. Although the front viewing effect is excellent, the phenomenon of color inconsistencies is prone to occur when viewed from the side at a large angle.

6. Anti-moiré

SMD adopts the form of particle packaging, and the black filling area is small, which can easily cause the moiré phenomenon (water ripples when shooting).

COB adopts planar packaging and has a unique laser treatment on the surface, which can effectively reduce the occurrence of moiré patterns.

7. Anti-image noise

SMD: Due to the large wavelength range of the selected chip, each pixel chip has a tiny noise.

COB: Select chips with extremely small wavelength differences and use unique optical lens technology to make the difference in brightness and color between pixels invisible to the naked eye. There is no picture noise at all, and the color is more saturated and pure.

Moreover, COB packaging mainly solves the problem of small spacing of LEDs, and its product lines are mostly concentrated below P1.25. For example, P1.25, P0.9, P0.6, etc. are almost all in COB packaging. Smaller dot pitch can bring higher resolution, resulting in higher clarity and better picture quality when displaying images.

8. Efficiency

The luminous wafers inside the lamp beads of the mainstream products of SMD screens are mostly made of formal assembly technology, and there are leads above the light source to block it, while COB screens are mostly made of flip-chip technology, and the light source is not blocked. Therefore, when the same brightness is achieved, the power consumption of COB screens is lower and more economical.

In addition, due to the low transparency of the epoxy resin used in SMD lamp bead packaging, the overall coating used in COB screens has higher transparency, further improving the economical use of COB screens.

Forward installation

Upside down Installation

After the COB screen is integrally packaged using a new process, the contrast ratio can be higher, reaching more than 20,000:1, while the contrast ratio of the SMD screen will not exceed 10,000:1. In comparison, the viewing effect of a COB screen when viewed from the front is closer to that of an LCD screen, with brighter colors and better details.

However, because COB screens cannot sort individual lamp beads with similar optical properties like SMD screens, the entire screen needs to be corrected before shipment. Although the front viewing effect is excellent, the phenomenon of color inconsistencies is prone to occur when viewed from the side at a large angle.

9. Cost

The production technology and processes of SMD are relatively complex, but due to the low technical threshold, there are more than a thousand manufacturers across the country, the competition is fierce, and the technology development is relatively mature.

The technical threshold for the production process of COB is high, and only a few manufacturers in China have R&D and manufacturing capabilities.

COB technology is still developing rapidly. Although its theoretical cost is lower than that of SMD screens, due to the low product yield rate, the current cost of COB screens is still at a certain disadvantage compared to SMD screens with pitches of 1.2 and above.

That’s all main differences between COB and SMD, pick the proper one according to your demand.